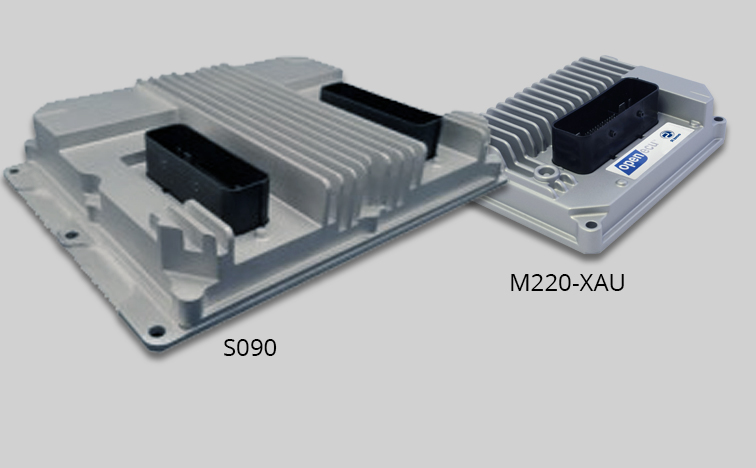

The M220-XAU is a unique variation of the M220 controller, specifically designed to be the master controller in applications using the S090 as a slave power driver box. This variation of the M220 provides inputs and outputs unique to motor control to seamlessly interact with the features of the S090 which include control of both a brushed and brushless DC motor.

The S090 is a versatile solenoid and motor drive slave power driver box optimized to support engineering development programs for the electrification of vehicular systems. It is designed for any system that uses PWM controlled actuators (valves, solenoids) and/or DC motors (brushed, brushless). It is an ideal solution for the most demanding actuators, capable of producing a total of 40A across its outputs.

- Designed to meet the needs of development engineers

- Die-cast aluminum sealed housing

- Proven sealed automotive connectors

- Robust electronics circuits suitable for an on-vehicle test environment

The combination of the M220-XAU with the S090 makes motor control simple by taking advantage of the M220’s existing VR sensor inputs and modified digital inputs, improved for high-frequency measurement. Software applications for using the M220-XAU as a master controller are streamlined with the availability of PWM outputs with synchronous sampling from the S090, providing feedback for measuring average motor line voltage, and decoders for measuring quadrature and 3-phase hall effect sensors.

Software Features include:

- Analog inputs synchronized to PWM Outputs Quadrature Decode Inputs (and Frequency Inputs)

- 3-phase Hall Decode Inputs

PWM outputs with synchronous analog inputs allow analog input signals (feedback from the S090’s motor drivers) to be read synchronously with the output waveform of the PWM control outputs of the M220. This analog input can be used for reading the average voltage for one of the 3-phase BLDC control lines.

The quadrature decode and frequency input provide a count of edges on the quadrature encoder since the last software iteration. This can be used to determine the encoder position or velocity.

This feature also provides the channel frequency for both the primary and secondary encoder sensors.

The hall decode input measurement decodes the signals from a 3-phase hall input, such as from a BLDC motor. This is compatible with 60° and 120° spacing configurations. This allows for accurate and consistent tracking of the motor angle in addition to speed, direction, and number of revolutions. This is often used to track the actuator position where the stop-to-stop motion requires several rotations of the motor.

Use Case

A Dana customer used the S090 for a high torque BLDC application for cold engine testing. The BLDC outputs of the S090 were used to drive an electric cam phaser. The master controller reads the speed of the internal combustion engine and subsequently commands the S090 to set the BLDC motor to the desired cam phaser position.

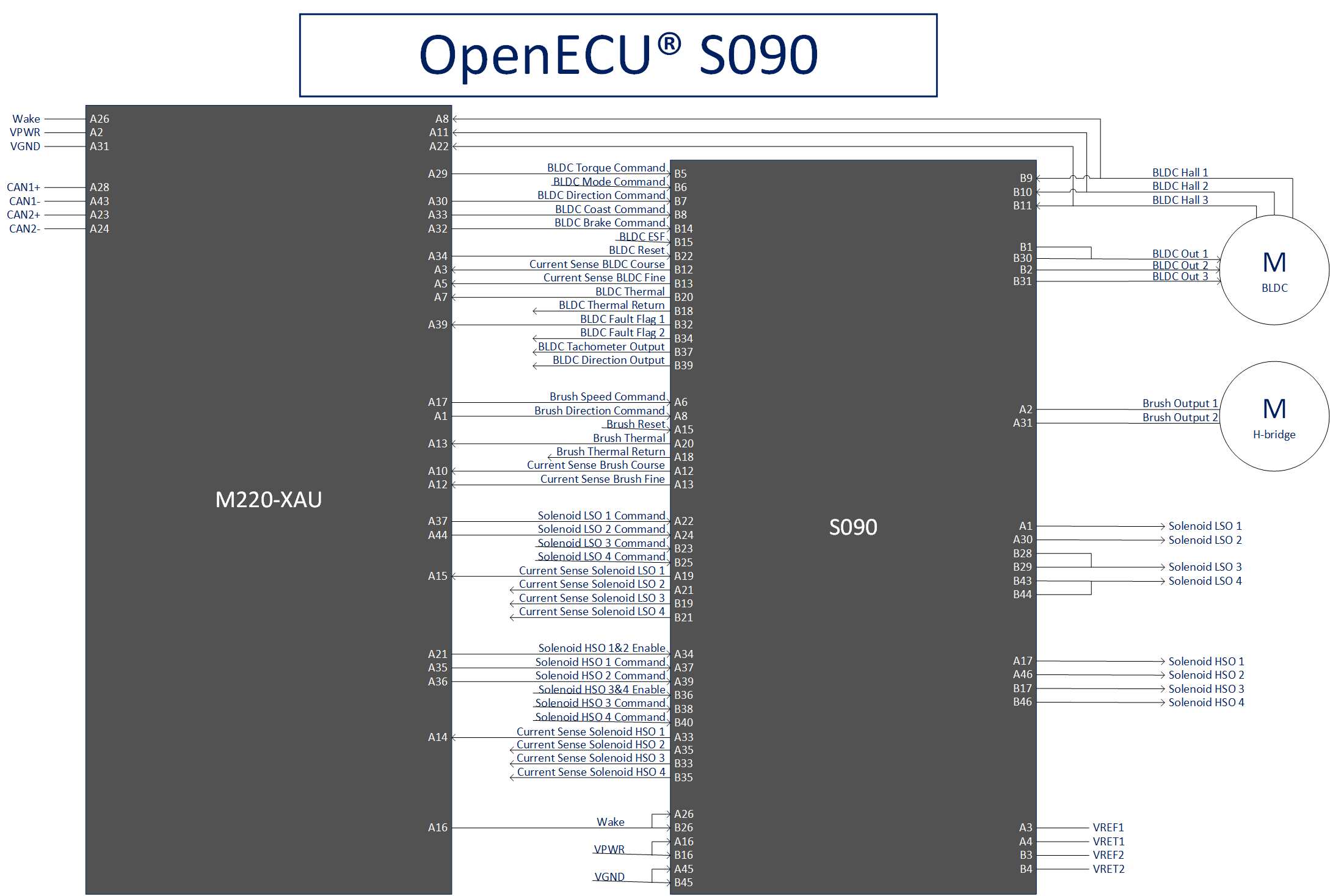

Proposed Pinout

The schematic below shows an example pinout of the M220-XAU paired with the S090.