Production and Prototyping Expertise

100+ million miles of production engine control software

150+ rapid controls prototyping & technology development projects

100,000+ ECUs in production using Dana’s developed software

The Dana team has extensive expertise and experience in managing the manufacturing of embedded controllers for series production, for both the OpenECU™ range of products as well as for products designed to meet a specific customer need. Expertise includes design engineering, test development, product cost optimization, component supply chain & global manufacturing supply base management, and can provide the resources necessary to manage a project through design, new product introduction, and volume production. Our capabilities cover all aspects of managing safety critical ECU production from supplier selection, process validation, PPAP, to in-process tool creation and specification.

Our experience spans all of the disciplines necessary for a successful production launch:

Dana’s approach to the management of controller production is flexible to account for different volume supply scenarios, working with the manufacturing facility that best matches the needs of Dana’s customers from a commercial and logistics perspective.

Learn More about Volume Production

The Dana Plymouth team has a track record of delivering highly reliable solutions for vehicle electrification. Dana’s ECUs are ruggedized, have high pin count and can be customized to suit your project requirements. The M560 and M580 ECUs have been certified by TUV SUD as ASIL D controllers and can be used for multiple applications in EV/HEV design, but are particularly suited for use as the main vehicle supervisory controller with integrated charge management functionality. Dana can offer a wide range of controllers and engineering services to support all aspects of EV development and production.

Learn MoreWe work closely with you to understand and refine your functional safety requirements (FSR’s) and then choose appropriate hardware and software solutions to meet the ASIL level of your project. Our flagship M560 is designed to satisfy safety goals up to ISO 26262 ASIL-D and is backed by the team at Pi Innovo with proficiency in delivering production 26262 projects.

Our staff is formally trained in 26262 and a Certified Safety Professional will be on your project.

For your projects, we provide full-service functional safety solutions that include:

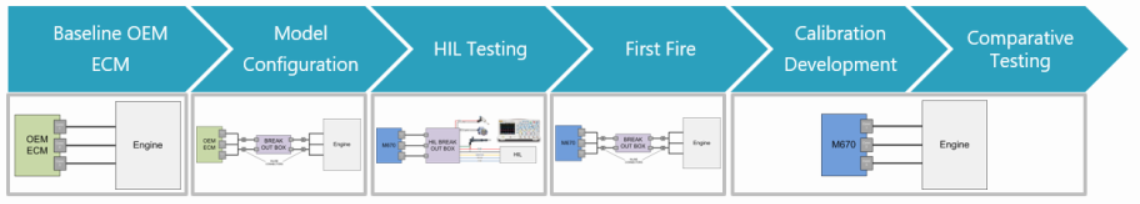

OpenECU has developed a systematic approach to replacing an OEM ECM, in order to provide full access to the engine control software and calibration. OpenECU engineers have been at the forefront of engine control development for 25 years, delivering class-leading specifications for performance, drivability, emissions and fuel-economy.

Learn MoreEngine Management Control Strategies are configurable Simulink Model Based Design control software designed to get most Diesel, Gasoline, or Gasoline Direct injection engines up and running quickly and ready for further development. Delivered as application source code to customers.

Learn MoreThe combination of Dana’s engineering consulting team and our OpenECU rapid controls prototyping platform has positioned us to support a broad range of production and prototype vehicle control systems programs.

Learn More