PLC Tuning

Power-Line Communication (PLC) is used during charging of electric vehicles around the world and is a must-have in today’s electric vehicle (EV) market. PLC allows the charging station (aka electric vehicle supply equipment or EVSE) and the EV to negotiate charging sessions, allowing various charging profiles and potentially to negotiate payment. Dana’s M560 and M580 modules have PLC capability built in.

Power-Line Communication (PLC) as depicted in ISO 15118-3 and DIN 70121 specifies power spectral density (PSD) limits of the HomePlug Green PHY PLC signal injection on the Control Pilot line for vehicle charging. HomePlug Green PHY is the standard for PLC signals used in vehicle charging called out in ISO 15118. Attenuation levels specified in the standards allow the differentiation between PLC signals on a connected charging station from crosstalk with a neighboring charging station. Higher than specified PSD on the PLC signal could cause disturbances in the Control Pilot detection, while having a signal too low could be interpreted as crosstalk or cause packet loss during the charging session. Having proper tuning provides the best environment for ensuring proper connection between a charging station and the electric vehicle.

Every vehicle model will have differences in mounting location and wiring harnesses for the charge controller module, which causes the attenuation on the Control Pilot line to vary. These differences may affect the entire spectrum of frequencies used for PLC, or only a subset. The default configuration of Dana’s modules will work in almost every situation, but with the different harness designs, there is the possibility of not meeting the DIN and ISO standards. Tuning, therefore, is essential for each vehicle model and Dana has the expertise on the tuning process of our M560 and M580 modules for use in our customer’s vehicle.

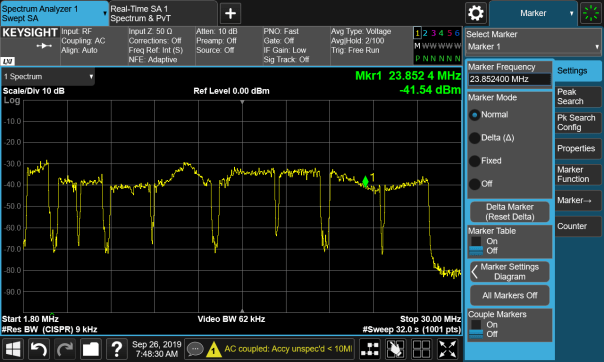

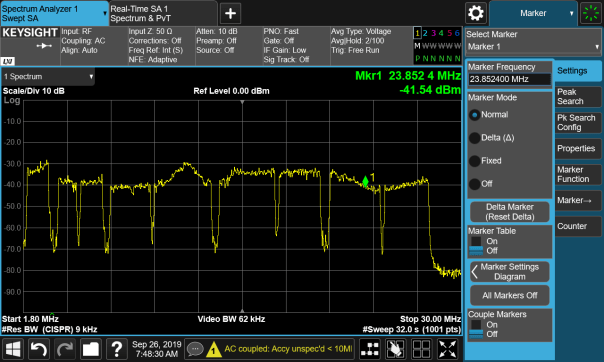

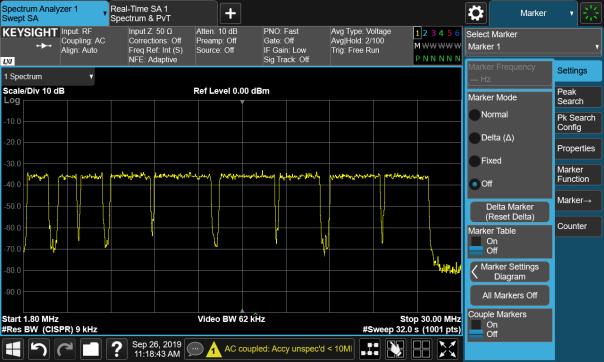

The maximum PSD of the PLC signal at the electric vehicle socket is -73dBm/Hz, with the target being -75dBm/Hz, as specified in ISO 15118-3. Dana can take measurements and, using some proprietary software, modify the PSD across the frequency spectrum to bring the entire PLC frequency band into compliance. Here is an example of a measurement taken on a pre-tuned and post-tuned module. Note that there are some frequencies with very low values, which are notched frequencies called out in the ISO and DIN standards. Additionally, note that the dBm value targeted is about -35dBm because with the resolution bandwidth used, the dBm/Hz ends up at the target of -75dBm/Hz.

Figure 1 Module Before Tuning

Figure 2 Module After Tuning

Once Dana creates an updated configuration for the customer’s vehicle, that configuration is used to program modules during production, eliminating the need for the customer to be concerned with having the correct configuration on the module. This configuration is not saved in the same memory as the application space, so the customer can continue to develop their vehicle application as usual.