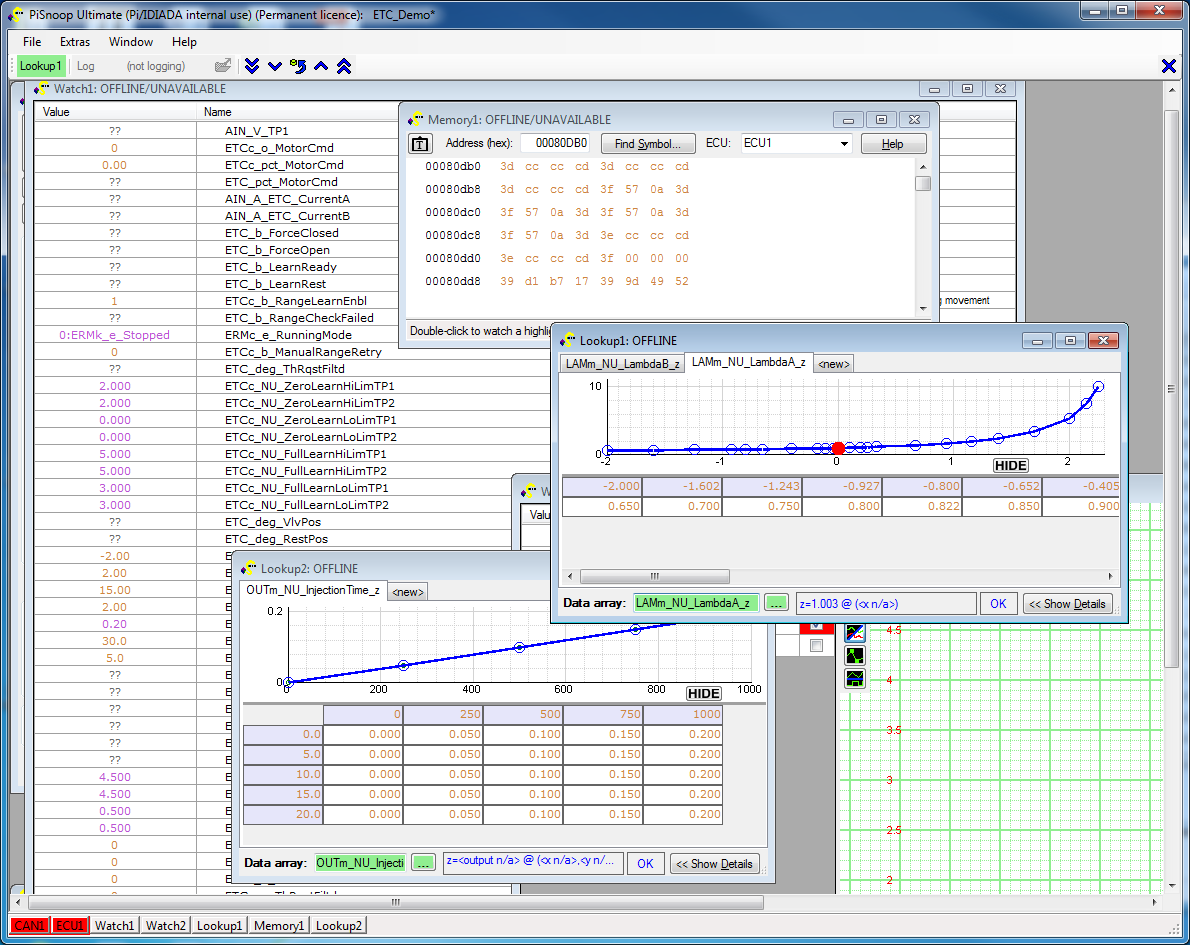

The OpenECU Calibrator software tool allows the user to interact with software while it runs in real time on an embedded system or electronic control unit (ECU). It uses a communications link to gain access to the memory of the ECU for read and write operations. It also loads information about the program running on the ECU so that it is aware of the memory layout, functions and variables present in the ECU software.

Calibration

The OpenECU Calibrator software tool allows access to ECU variables and memory in real-time, using CAN. It supports access to structured data, arrays, pointers, and bitfield data-types. Users may view and edit within the windowed user interface, or export to Excel for further analysis.

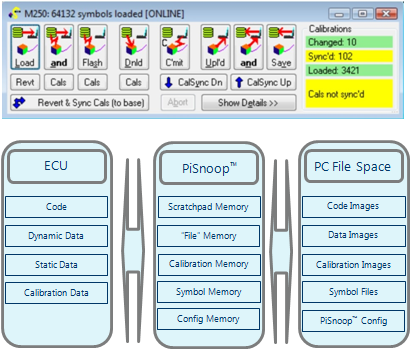

Reprogramming

OpenECU Calibrator software tool provides flexible access when working with ECU memory.

- Load Symbols & Images

- Symbols From linker Files (ELF/.AFX/.OUT) Or ASAP 2 Description Files (.A2L)

- Data Images From Linker, Parameter And Hex/S-record (Image) Files

- Code Images Hex/S-record Files

- Download New Program & Blocks Of Memory

- Code, Calibrations, Data Values

- Upload Blocks Of Memory

- ECU Memory (RAM/Read-only)

- Save Blocks of Memory To Files

- For Analysis, Modification or Future Load

- Calibration Download/Synchronisation using CCP

- Single Click To Re-flash ECU With New Build

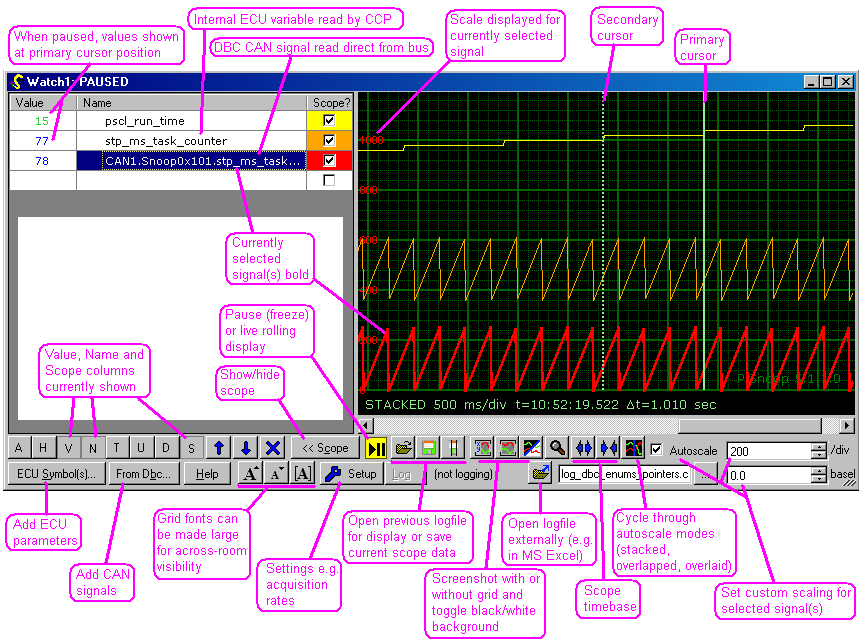

Data Monitoring

OpenECU Calibrator software tool provides a feature-rich view to monitor data exchanged with the ECU. OpenECU Calibrator Oscilloscope View provides the following features:

- Real time view of selected values

- Pause for detailed analysis

- Examine logged data

- Sample period down to 1 millisecond

- View multiple ECU parameters simulaneously

- CAN signals

- Scaled display output

- Scaled fonts for viewing

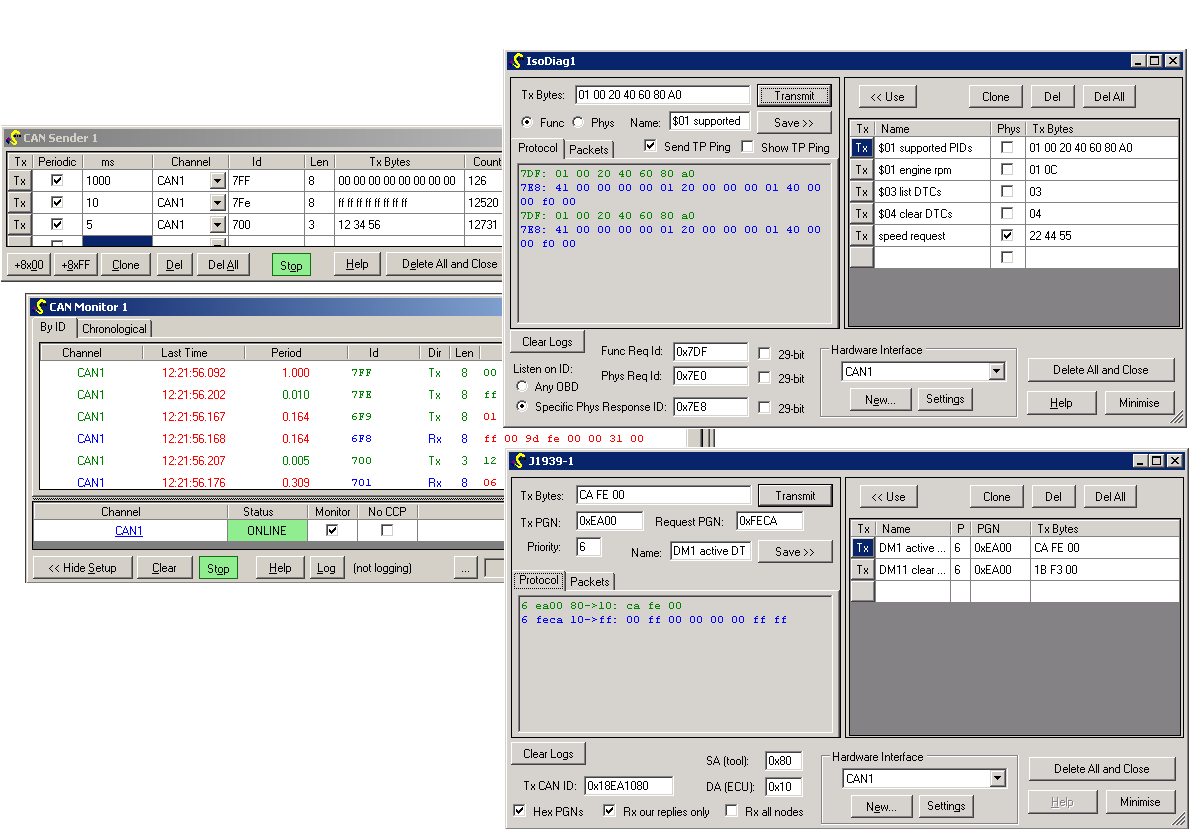

CAN Monitoring

The OpenECU Calibrator software tool allows provides a comprehensive set of tools to the user for working with the CAN bus.

- Single & Periodic message support to 1 millisecond period

- CAN Database (*.dbc) support for CAN data management

- Full support of multiplexed signals (cyclic transmit & receive)

- Message filters (single-click blocking, and more advanced)

OBD Protocol

In addition, the OpenECU Calibrator software tool offers user enhanced CAN handling to support both ISO-15765 and SAE J1939 message protocols.

The OpenECU Calibrator System Requirements

- Windows 10/XP/Vista/7/8 32 or 64-bit with .NET framework 3.5

- 2 GB RAM

- Any Kvaser, Vector or PEAK-System (PCAN) CAN interface

- For non-CAN ECUs, a serial interface via RS232 or UDP/IP on the PC

- OpenECU™ or similar application built with Diab 5.x, CodeWarrior for HC(S)12 v5.0 or CodeWarrior for MPC55xx v2.7 compiler (if debug-style access required)

- ASAP2 (.A2L) file required otherwise

- ECU with CCP v2.1 or Keyword Protocol 2000-3/UDS support (for memory access and flash reprogramming)

- Any CAN-based ECU (for general diagnostic and CAN functions)

OpenECU Calibrator software tool Updates v9.6.8.0

- Fixed LIN bug: sometimes changing master node transmit value had no effect (due to read-back of simultaneous bus transmission intended only for rx packets).

- No longer cycling LIN bus status when changing slave response values, which caused audible chirrup from devices and response glitches on master side.

- Workaround for problem whereby given a list of LIN Sender slave responses, message edits didn’t always have an effect. (Seems to be hardware-driver related.)

v9.5.0.0

- LIN support added using Kvaser interfaces

- LIN Description File (.ldf) support included for message schedule and signal access