Dana works with Contract Electronics Manufacturing partners and their suppliers globally to ensure deliver of the highest quality product in the most efficient way. During the development phase of a particular controller, Design for Manufacturing, Assembly, and Test (DFMAT) is a high priority for Dana’s engineering team, and involves all aspects of the final product. Some of the key suppliers and considerations are discussed here.

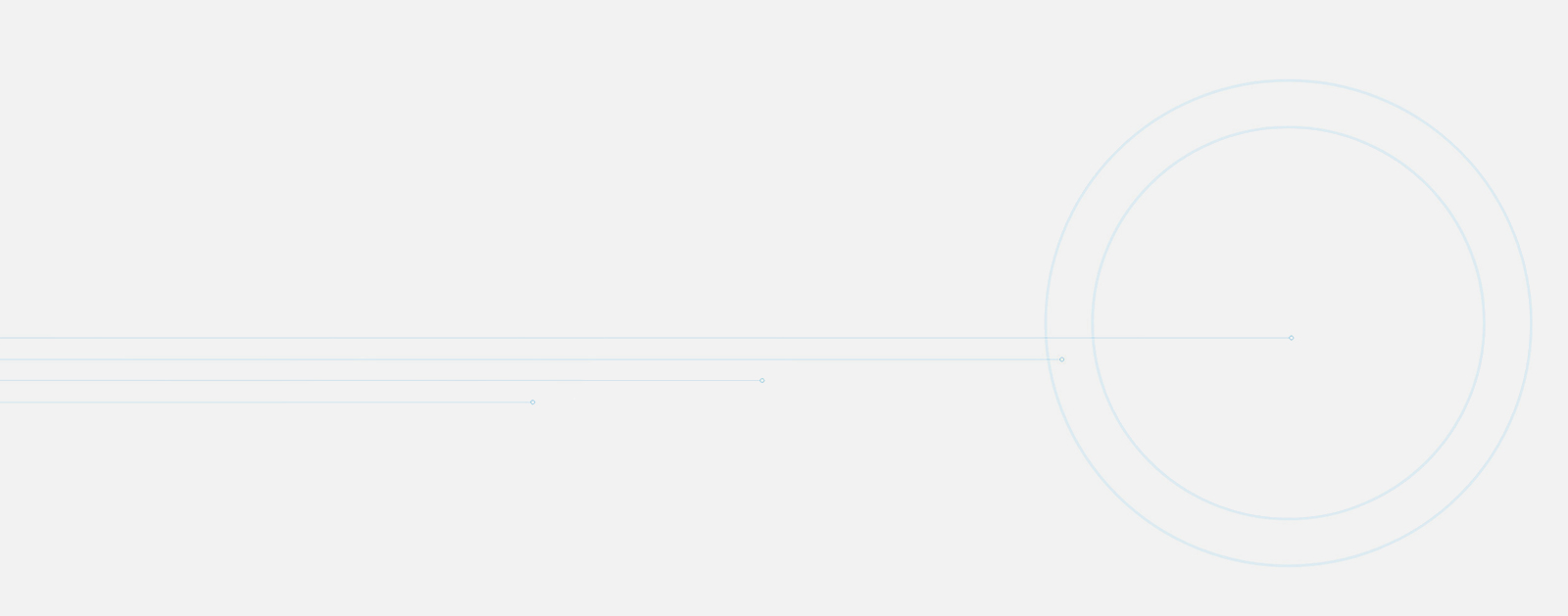

Enclosure Producer

Dana purchases enclosures, housings and lids, from qualified suppliers of milled blocks, castings, or plastic injection molding. Most OpenECU™ enclosures are custom designs to fit the PCB, support the connector(s), dissipate heat, and provide protection from harsh environments. Most enclosures are environmentally sealed, using a semi-permeable vent.

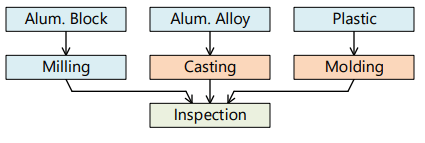

PCB Fabricator

Dana purchases Printed-Circuit Boards from qualified suppliers, who build the custom designs using CAD files provided by Dana. Many PCBs are produced to IPC-A-6012 Class 3 standards. PCBs featuring 4 to 8 conductive layers, and balance contrary thickness constraints from fine-pitch Ball-Grid-Array package resolution and high-currentcapability traces. PCB materials are selected for compatibility with ECU environmental, self-heating, and electrical conditions.

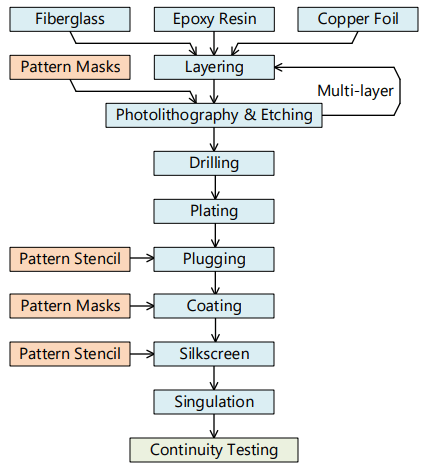

PCB Assembly

Dana works closely with contract manufacturing facilities to assemble custom PCBs to IPC-A-6012 Class 3 standards. Components and alternates are controlled by Dana designs. Key parts and assembly operations are inspected or tested. Most inspection and testing steps are highly automated, including solder paste thickness, component placement, and In-Circuit Test (probe). Where appropriate, optical inspection is supplemented by X-Ray. The vast majority of components have Surface Mount Device (SMD) packages; through-hole, “odd” components, such as connectors, are soldered with a robotic wand. Microcontrollers are programmed with test software, serial number, and other manufacturing information before proceeding to final assembly.

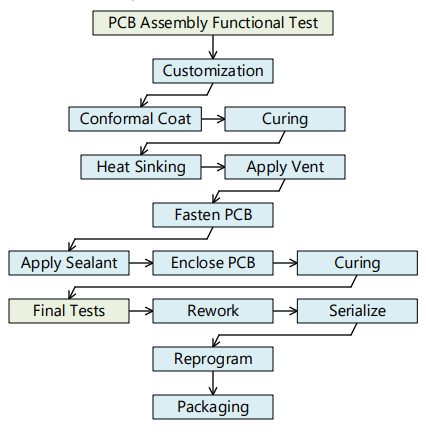

Final Assembly

Final assembly operations and sequencing varies based on product needs. Dana designs the test vectors appropriate for the ECU: these are often used prior to assembly, and always after assembly is complete. Any conformal coating is applied to the PCB assembly prior to applying heat sink material and fastening to the housing. Any vent and sealant is applied, then the lid is placed to enclose the PCB assembly. ECUs that pass final testing are issued a product label showing the part number and serial number, and may be reprogrammed for the application of the customer. Low-volume customizations are realized by producing one of OpenECU’s standard products, applying the circuit options prior to sealing, and making the appropriate part number changes.

Programming Stations

For factory operations, Dana uses custom-built stations to make programming fast and repeatable. The stations improve process speed and repeatability by reducing the amount of manual operations the operator is required to do. Reliability and ease of servicing are also important considerations when designing fixtures. Keeping that in mind during design will reduce down time from regular regular servicing.

Dana has developed a number of in-line production tools and programming stations to meet the needs of customers who require application software flashed at the end of the ECU production line, before modules are sent to the vehicle assembly plant. Dana’s programming stations quickly and reliably program our ECUs using OpenECU’s CAN interface. Reliable operation is ensured by automating the maximum number of operator tasks withing the programming station. Dana’s programming stations automatically check metrics of the loaded software to ensure that the code download was successful. Our programming stations also contain advanced logging capabilities for process monitoring and debugging.