The validation process is an iterative process that helps refine the design and fix any unforeseen problems from integrating the design pieces together . FMEA and worst-case analysis give great indications of design suitability , but since there are always parasitic parameters and real-world interactions that are time-consuming and expensive to model , checking the design becomes easier through testing.

The systems requirement defines what system level tests are appropriate for the development and the test strategy describes the basic functional/parametric tests and breaks validation tests into pre-DV, DV, PV, and production phases. As development progresses, additional test documentation is created such as a DV Plan, a Production Test Requirement, and a variety of test scripts.

Testing standards have been developed to help designers and OEMs have confidence that the product will survive the environmental conditions to which they will be exposed . Dana uses typical automotive test standards when doing module validation. Customer standards and standards outside of the automotive industry (such as aviation ) have also been used for custom designed product.

| Test Name | Specification |

| Immersion | IEC 60529 |

| Thermal Shock | ISO 16750-4 |

| Power Temperature Cycle | ISO 16750-4 |

| Vibration | IEC 60068-2-64 |

| Radiated Emissions | CISPR-25 |

| Conducted Emissions | CISPR-25 |

| Radiated Immunity | ISO 11452-2 |

| ESD | ISO 10605 |

| Short Circuit | ISO 16750-2 |

| Transient Immunity | ISO 7637-2 |

| Reverse Polarity | ISO 16750-2 |

| High Temperature | ISO 16750-4 |

| Low Temperature | ISO 16750-4 |

The first samples, see the build stage moving into the integration test in the V-model, go through a full bench checkout to make sure all the designed features work as expected. Pre-DV tests are done in-house , which include a variety of electrical tests and temperature tests, such as high-temperature, low-temperature, short circuits, and doing a baseline EMC checks. Design improvements are implemented, based on findings in Pre-DV, and the next sample modules are made, which will be put through the entire design validation plan. Design improvements are made iteratively bringing the final product to the point of process validation, verifying that the ECU will be built correctly every time at the chosen production facility.

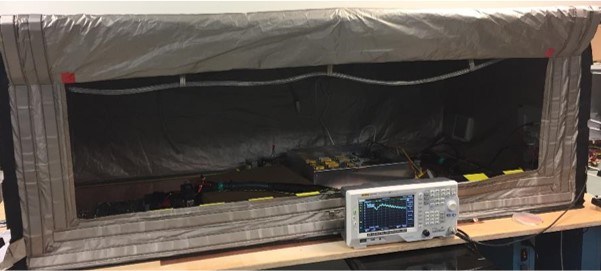

Once the initial specifications are ready, DV/PV tests are run within Dana’s facility when possible. When this is not feasible (due to large capital constraints such as EMC chambers or mechanical fixtures), Dana works with local test laboratories to perform the tests. Dana’s Plymouth office is centrally located to both EMC & environmental test laboratories. TUV Sud America, an EMC test provider that Dana regularly uses, is located less than one mile away from Dana’s office. Outsourced mechanical tests are similarly close, with NTS Detroit being less than a thirty-minute drive from the Dana office.

Pre-DV

For new ECUs with novel circuitry or mechanical concepts, pre -DV is used to refine the design prior to a full DV test battery. Pre-DV tests target higher risk design components to address critical flaws early in the design cycle. For example, if the OpenECU™ project has a new enclosure concept, pre-DV may target vibration, mechanical shock, and drop tests. Pre-DV testing provides a head start on the development of the test infrastructure including vehicle simulators/load boards, harnesses, and functional test scripts. Additionally, pre-DV helps refine product documentation as Dana engineers must document interfaces and load profiles internally and for outsourced test facilities.

EMC Tent

Dana develops high-quality ECUs , which survive harsh environments by using robust testing. Typical testing includes the following list, though these can change depending on the DV/PV, expected environment, and customer requirements for custom ECUs.

DV

After pre-DV issues are resolved, an OpenECU is ready for DV. The DV tests are designed to verify that the OpenECU meets the functional and environmental requirements that were described in the systems requirements document. (INSERT LINK to 15). Some common types of DV tests include:

- EMC, Emissions (CISPR25)

- EMC, Immunity (ISO 11452)

- Electrical Tests (ISO 16750)

- Mechanical Tests (ISO 16750)

The tests types ab ove represent only a handful of tests that Dana runs for OpenECU controllers. For a complete list, DVP&Rs can be provided on request for any OpenECU product. If you have custom requirements for testing, Dana can also run additional tests to provide a tailored DVP&R that meets your requirements. We have experience with multiple OEM specific validation standards including (but not limited to):

GMW 3097, GMW3172, BMW GS 95002, MB 10284, FCA CS.00054, JLR-EMC-CP, and VW 80000

Dana can also provide support for system integration & validation testing or dynamometer testing through our systems engineering group.

Learn more about Design Validation

PV

PV testing is typically performed on ECUs that are designed for series production vehicles. PV tests verify that the production processes used by the contract manufacturer builds ECUs correctly. Depending on what was tested in DV, PV testing may be tailored to reduce effort & cost where the processes were sufficiently covered by the earlier DV tests. PV data proves the effectiveness of a variety of production processes including PCB assembly, in-circuit testing, and end of line testing.